LT CT & PT Transformers

Tape insulated/Epoxy Resin Cast construction up to 660V for metering, protection, and control applications in low-voltage systems.

Outdoor Oil Cooled CT & PT

High-voltage distribution components up to 33KV with oil impregnated paper construction for reliable outdoor operation and accurate measurement.

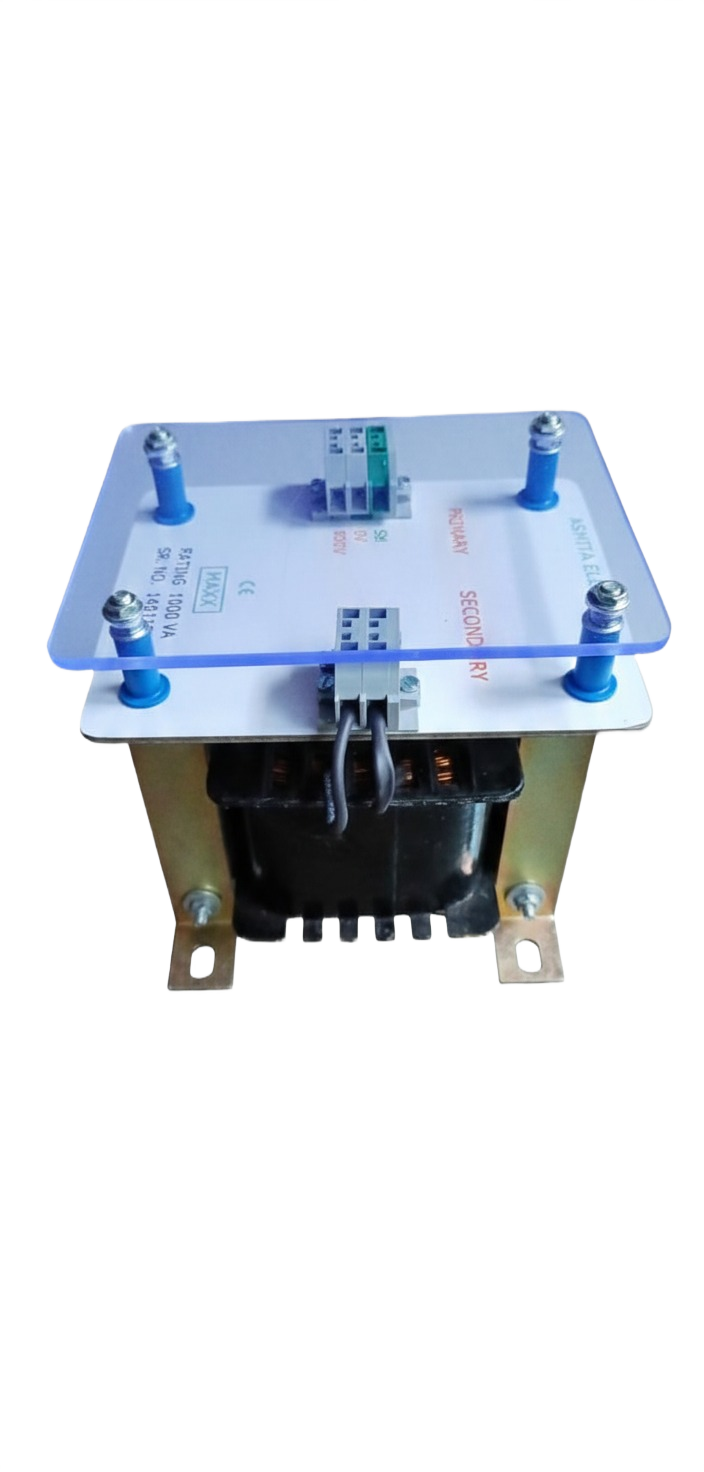

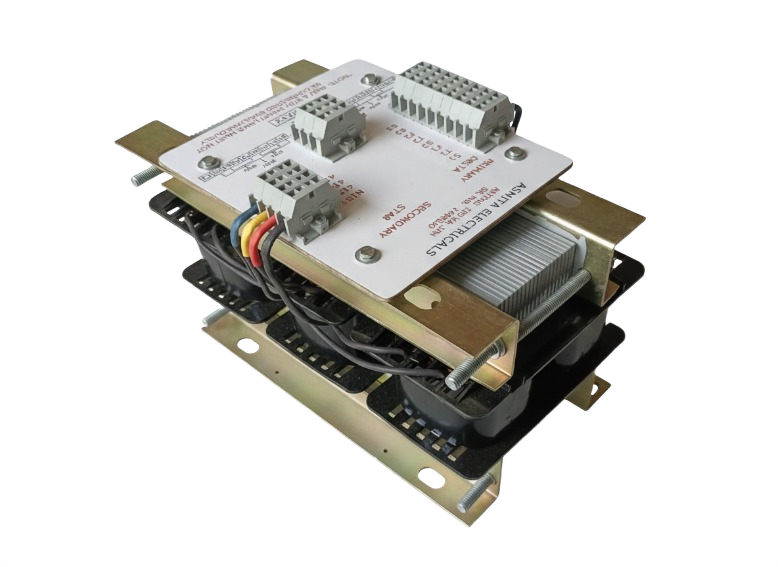

Control Transformers

Single and three phase transformers providing stable and isolated control voltage for automation, instrumentation, and control circuits.

Lightning Transformers

Specially designed to withstand lightning surges and transient over-voltages, ensuring reliable operation and protection of electrical systems.

Auto Transformers for Motor Starters

Oil cooled auto transformers for motor starting applications (10HP to 600HP) to reduce starting current and mechanical stress.

Line Choke

Limit inrush current, reduce harmonics, and protect sensitive equipment from voltage spikes and transients in electrical power systems.

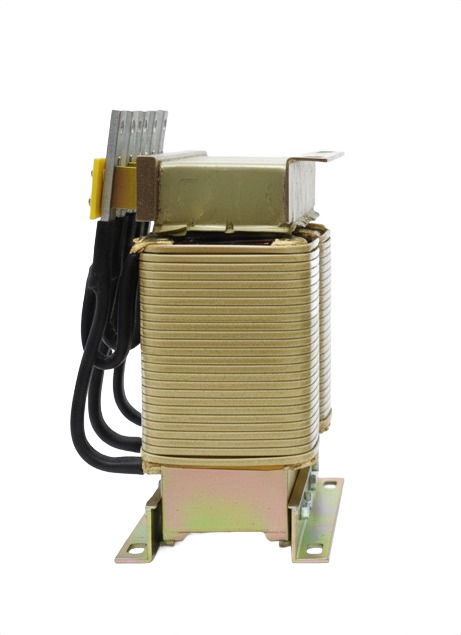

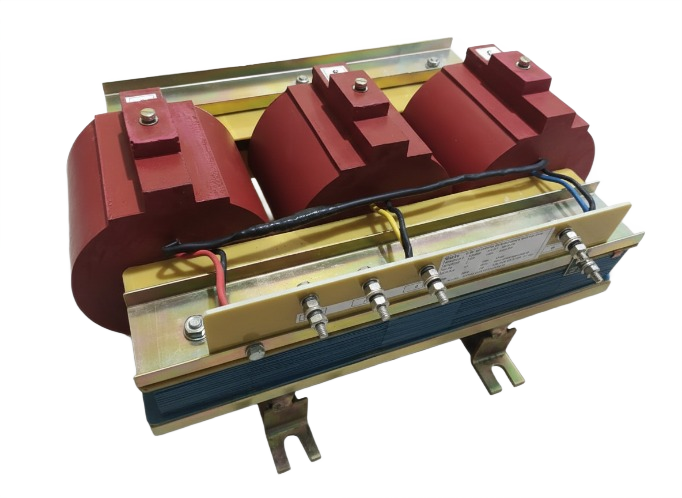

Copper Wound LT Reactor

High efficiency, lower losses, and superior thermal performance copper wound reactors for critical and continuous-duty applications.

Aluminium Wound LT Reactor

Cost-effective and lightweight aluminium wound reactors providing reliable performance for general-purpose industrial applications.

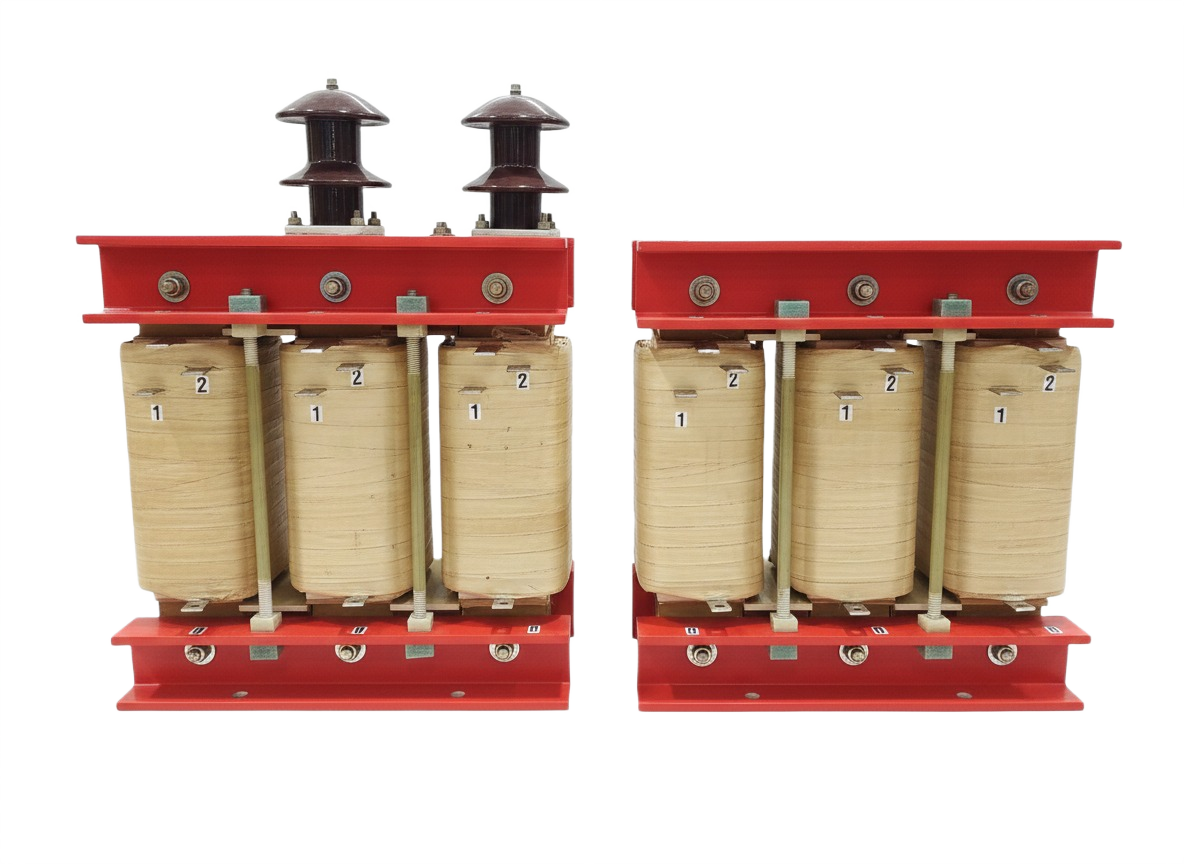

HT Dry Type Air Core Reactor

Dry type, air core reactors for medium and high-voltage power systems up to 33KV with no core saturation under fault conditions.

CT-PT Combine Unit

Integrated CT-PT units up to 33KV for 3-phase 3-wire and 3-phase 4-wire systems with oil impregnated paper construction.